Atelier TUFFERY workshop, a family tradition, in Florac (part 2)

FR - Continuation of our fascinating feature on French know-how, written in collaboration with Myriam from the Atelier TUFFERY in Florac.

Your workshop rotates, meaning that your dressmakers swap workstations. How is this efficient? Does this system allow you to improve your manufacturing methods and consider possible changes?

Absolutely. We have focused our production and recruitment on multi-skilled jobs, meaning that the garment makers are trained in-house in several or all of the 80 operations involved in making a pair of jeans. In the end, it takes between a year and a half and two years of training to get to grips with the complexity of the specific machines used in the industrial manufacture of jeans.

This way of rethinking manufacturing is not efficient ‘in accounting terms’, because we take much longer than industrial workshops (of the 1960s type) where assembly-line work is still the rule, with people working 8 hours a day at the same machine, doing highly repetitive work. But it performs well in many other areas that are important to us, such as workplace fulfilment, well-being and the empowerment of the people behind the machines.

The result? Little or no staff turnover, and a team that is now both locomotive and experienced. We can react quickly, and we can vary our product range without having a single product. This also helps to diversify the team's operations.

What's more, we have the skills and equipment to do everything in-house, from design, prototyping, selection of materials, pattern-making and so on, through to manufacture, repair, sales, marketing and communication... A wide range of expertise that enables us to respond quickly to markets, opportunities, custom orders and so on. Our business model is as exciting as it is complex.

|

We have focused our production and recruitment on multi-skilled positions, in other words, garment makers are trained in-house in several or all of the 80 operations involved in making a pair of jeans.

|

Your collection is available in jeans, jackets, dresses, shirts and duffle coats in your showroom... We can also find accessories such as gloves, a fine example of a jeans/leather duo with Maison Fabre, aprons, bananas, belts, caps, etc. How do you work on your collection and designs?

As I said, we have in-house design and manufacturing processes. Then we collaborate with other brands or other French workshops, on products where each entity can bring its own touch. Take gloves for Maison Fabre, for example, which are manufactured in Millau in their historic workshops dating back to 1924, using French wool twill from our Tissage d'Autan workshop.

We have many other partnerships. We work with Le Sac du Berger in Aveyron for the leather components of our denim aprons, for example.

For the last 2 years, we've also been working with the French knitwear specialist Saint James, for whom we make jeans and who also makes us some beautiful French wool jumpers to complement our winter collection.

|

Made-to-measure, a unique experience where our experts are at your disposal to organise a personalised meeting. Our tailor-confectioners, specialists in historic denim, will guide you through each stage of the creation process, highlighting their expertise and passion for their craft. What's more? The retouching option, so you can adjust your jeans to your own body shape, the online boutique and second-hand sales. And what about the made-to-measure experience?

|

What's more? The retouching option, so you can adjust your jeans to your own body shape, the online boutique and second-hand sales. And what about the made-to-measure experience...

Yes, we offer different services to our clients.

We adjust the jeans to the length of your legs on the spot, to the nearest centimetre. It's done in just a few minutes and it's free. A little tip: you'll leave with your inseam length, so for future purchases, even online, you can let us know so that we can take care of the alterations. You then receive your jeans ready to wear.

We take the whole value chain into account and follow our products right through to the end of their life too. First of all, there's the repair, which is why we are approved repairers. We offer a repair bonus to encourage people to mend rather than throw things away. We also have a second-hand platform, for the resale of Tuffery products between private individuals, to always avoid waste and extend the life of our products as much as possible.

Another premium service is our made-to-measure offer, where, following the example of founder Célestin Tuffery, we organise a personalised meeting with the customer, taking measurements, adapting the cut and material, and making a selection according to the customer's desires.

Making only what we are sure to sell is one of the major foundations of our model, in contrast to the ready-to-wear of fast fashion. You might say that this is common sense. But that's not what's happening in the majority of the clothing market in France (95%), where outsourced overproduction to cut costs causes waste and catastrophic environmental pollution (clothing dumps in Ghana, for example). We all have these striking images in our heads, seen in the news reports.

|

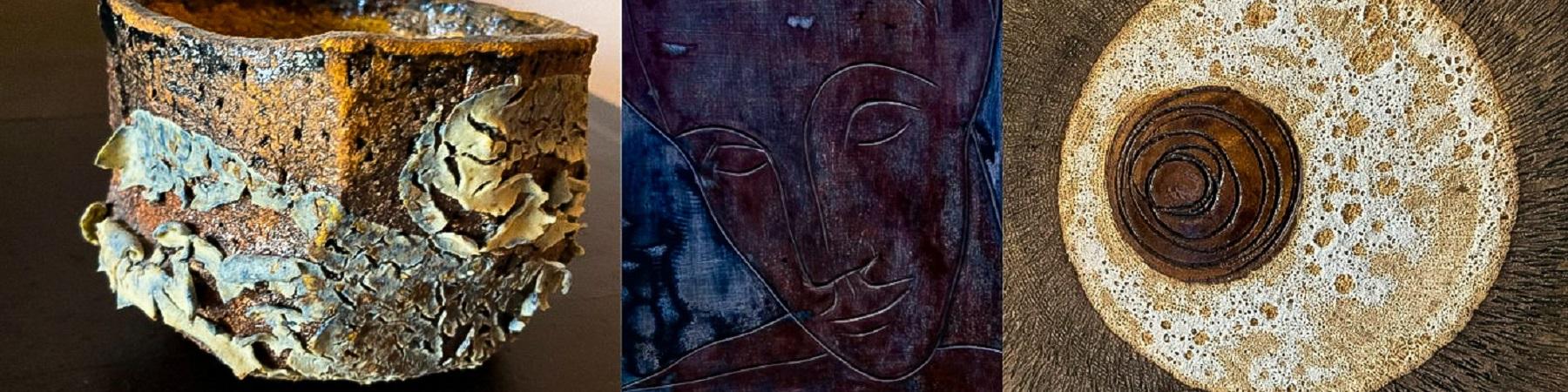

The ‘Héritage de Célestin’ capsule collection celebrates our heritage while reinterpreting it with a contemporary twist. In collaboration with Montpellier artist @Arnaud De Jesus Gonçalves, aka Arkane, we have pushed back the boundaries between craft and art. This project is more than just a collection. It's a creative adventure in which each piece embodies the essence of our history while exploring new artistic perspectives.

|

What else can we offer you? A guided tour of your studio, an ideal way to get a better idea of the off-site work, and a programme of activities in your open-plan, outdoor space. Concerts, exhibitions, exclusive moments of sharing that create a link between the Atelier TUFFERY and the participants.

How do you go about programming your events?

We've also diversified our activities by innovating with our factory. It's a place to live, not just a place to work.

We organise guided tours to show as many people as possible around the Atelier TUFFERY, both in the shop and in the workshop, and to raise awareness of our model, proving that more responsible consumption is possible.

More and more people are aware of the impact of their consumption. It all started with food, with seasonal produce, organic food, less packaging... It's exactly the same thing we're thinking about when it comes to clothing. Getting the product directly from the producer is better for the planet. What's more, when the product is comfortable and attractive... It's also important for us to have products that our customers want.

So Atelier TUFFERY is a place to live, a place to party with a summer programme featuring musical groups, theatre groups, a guinguette serving platters made from local produce... Above all, it's a collaborative effort in which many members of the team are active. It's a great way of bonding people, and we love it!

Many thanks to Myriam for collaborating on this article and for her warm welcome and personalised guided tour of the workshop.

Many thanks to Myriam for collaborating on this article and for her warm welcome and personalised guided tour of the workshop.

Read L'Atelier TUFFERY, a family French know how in Florac (part 1)

The right address: Atelier - Boutique TUFFERY, ZA Saint-Julien-du-Gourg, 48400 Florac. Open Monday to Saturday, 9am to 12pm and 2pm to 7pm. Boutique de Montpellier - Atelier TUFFERY, 13 rue du jeu de paume, 34000 Montpellier. Open Tuesday to Saturday from 10am to 7pm. Follow @AtelierTuffery on Instagram and Facebook.